中國爆發不肖業者將二手褲襪回收後,製成毛巾販售。

毛巾的製作流程通常包括以下步驟:

通常使用純棉或竹纖維等天然纖維作為毛巾的原料。這些原料吸水性好,觸感柔軟,適合用於製作毛巾。選擇好的原料後,將紗線放入織機中進行編織。根據需要的毛巾規格和設計,選擇不同的編織方式,如平紋、斜紋等。在織好的毛巾上進行印染處理,可以添加顏色和圖案,以使毛巾更加吸引人。將印染好的布料進行剪裁,根據設計尺寸製作成毛巾的形狀和尺寸。將剪裁好的布料進行縫製,包括縫邊、縫標和裝飾等,以確保毛巾的整齊和耐用。

將縫製好的毛巾進行洗滌處理,去除表面的污垢和殘留的化學物質,使毛巾更加柔軟和舒適。對製作好的毛巾進行質量檢驗,確保符合相關的標準和規定,然後進行包裝,準備上市銷售。儘管毛巾在製作過程中經過多次洗滌和檢驗,但仍然存在衛生疑慮的原因:

汙染源:在製造過程中,如果工廠環境不潔淨,原料、設備或人員可能會受到污染,導致製成的毛巾存在衛生問題。

化學殘留:在染色和加工過程中使用的化學助劑,如染料、漂白劑和軟化劑等,如果未能徹底去除,可能會殘留在毛巾上,對人體健康造成潛在威脅。

細菌滋生:如果在製作過程中未能嚴格控制衛生條件,或者在包裝和儲存過程中未能防止外界污染,毛巾表面可能會滋生細菌,導致使用時帶來健康風險。

因此,消費者在購買毛巾時應注意選擇正規生產商和可靠品牌,並注意質量檢驗標準和衛生認證,以確保所購買的毛巾符合相關衛生要求,並進行必要的清潔和消毒處理。

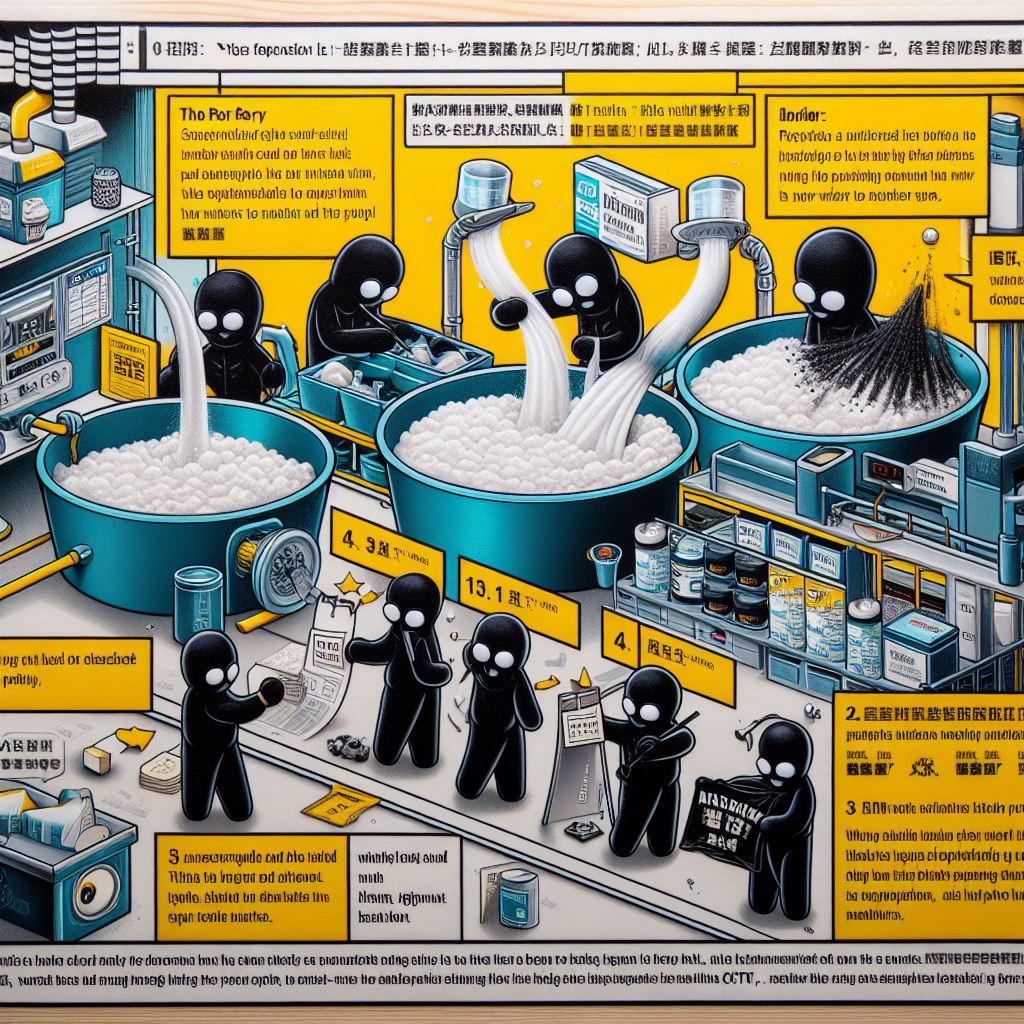

在3月15日的晚會上,中國央視揭露一個醜聞,有不肖業者將二手褲襪回收後,經過工廠重新處理,製成新的毛巾。在這個製作過程中,廠商會在黑心棉中添加大量的漂白粉、螢光劑和滑石粉。然後使用包漿機器攪拌混合,最後員工直接開始包裝,將這些毛巾運送到各大超市販賣。

The production process of towels typically involves the following steps:

Material Selection: Natural fibers such as pure cotton or bamboo fibers are commonly used as raw materials for towels. These materials have good water absorption and soft texture, making them suitable for towel production.

Weaving: Selected yarns are placed into weaving machines to weave the fabric. Different weaving methods, such as plain weave or twill weave, are chosen based on the desired specifications and designs of the towels.

Printing and Dyeing: The woven towels undergo printing and dyeing processes to add colors and patterns, making the towels more attractive.

Cutting and Stitching: The printed and dyed fabrics are then cut into the desired shapes and sizes according to design specifications. They are stitched together to ensure neatness and durability, including hemming, labeling, and decoration.

Washing and Inspection: The stitched towels are washed to remove surface dirt and residual chemicals, ensuring that the towels are soft and comfortable. Quality inspections are conducted to ensure compliance with relevant standards and regulations before packaging and preparing for sale.

Despite undergoing multiple washing and inspection processes during production, there are still concerns about hygiene due to several reasons:

Source of Contamination: If the factory environment is not clean, raw materials, equipment, or personnel may become contaminated during the manufacturing process, leading to hygiene issues in the produced towels.

Chemical Residues: Chemical additives used in dyeing and processing processes, such as dyes, bleaches, and softeners, if not thoroughly removed, may leave residues on the towels, posing potential health threats to consumers.

Bacterial Growth: If hygiene conditions are not strictly controlled during production or if external contamination is not prevented during packaging and storage, bacterial growth may occur on the surface of towels, posing health risks when used.

Therefore, consumers should be cautious when purchasing towels, choosing products from reputable manufacturers and reliable brands, and paying attention to quality inspection standards and hygiene certifications to ensure that the purchased towels meet relevant hygiene requirements and undergo necessary cleaning and disinfection processes.

During the March 15th evening program, China Central Television (CCTV) exposed a scandal involving unscrupulous businesses recycling second-hand underwear and socks to produce new towels. In this production process, manufacturers add large amounts of bleaching powder, fluorescent agents, and talcum powder to inferior cotton. The mixture is then stirred using a pulping machine, and the resulting towels are packaged and sold in supermarkets.

照片:DALLE3

- 1

- 2

- 3

- 4